Please read before ordering

About screen printing

What is screen printing?

"Screen printing" and "silkscreen printing" are methods of printing ink directly onto clothing or goods using a plate.

To create the plates, a separate plate is required for each color, so normally the plate-making fee would be several thousand yen per plate, but PRINTEEZ offers a free plate-making service for orders of 10 or more items of the same design . However, if you order 9 or fewer items, the following additional charges will apply.

When making new plates for 9 or fewer sheets: A plate-making fee of 2,000 yen per plate is required.

For additional orders of 9 sheets or less: A color change fee of 1,000 yen per plate will be charged.

*If you order using the design simulator, the above amount will be automatically added if you change the printing category. (For details, please see How to Order / Processing Fees and Additional Fees.)

Screen printing features

-This is the most common and popular printing method, producing beautiful results.

- Recommended when you need a large number of the same design.

- It is resistant to fading and durable even after washing.

-We have a wide variety of inks available, so you can print in the color of your choice.

・PRINTEEZ does not charge plate fees for additional production on a semi-permanent basis (in principle, same material/same position).

・One plate is required for each print color in one area.

・If you order 9 or less sheets, 2,000 yen will be charged per sheet.

- Processing may not be possible in some locations, such as near stitching or edges.

- With polyester products, over time, there is a possibility that the color of the fabric may bleed (reverse sublimation) onto the printed surface.

Maximum screen print size

As a general rule, the size is within W350mm x H400mm, but this varies depending on the product, so please refer to the product details.

Screen printing precautions

We recommend creating data with a fill of 1pt (0.35mm) or more and a cutout of 2pt (0.7mm) or more. Anything less than this may result in the data being crushed or not being displayed clearly. Any data submitted below these values that is crushed or blurred will not be eligible for return.

・Halftone printing is also possible, but in that case please submit the data at actual size, 300 dpi or less, and a screen frequency of 40 or less. Also, just to be on the safe side, please submit the original data before halftone processing.

- Print colors are expressed in RGB, which has a wide color gamut, on PC and smartphone monitors, but are actually expressed in CMYK, which has a narrow color gamut. Therefore, vivid colors in the RGB color gamut are replaced with approximate colors in CMYK. Also, while colors created in RGB are a combination of light, colors created in CMYK are a combination of actual inks, so the color development, saturation, brightness, etc. may be different from the color you desired. The finished color may also vary depending on the type of fabric.

T-shirt line width test

About halftone processing

If you submit a grayscale image when placing an order using the simulator, and no instructions are given by the customer, we may apply halftone processing at our discretion.

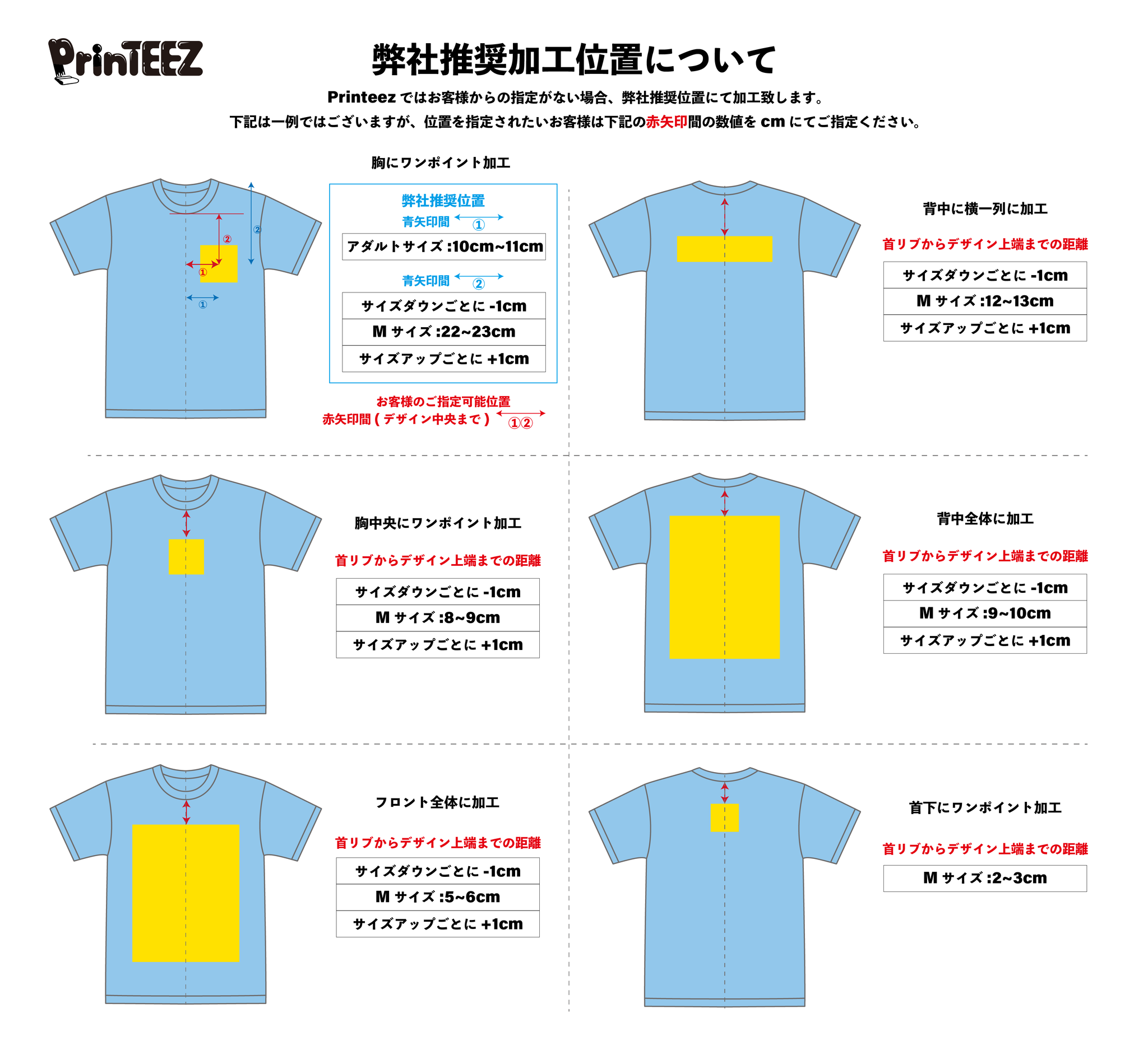

Regarding position specification

1. Regarding height specifications, for screen printing, please specify the measurement from the bottom edge of the rib at the neck. If you specify the height from the top edge, there is a possibility that the position may be misaligned due to individual differences in the rib, so returns and exchanges are not possible. If you want to specify the exact position, please specify the distance from the bottom edge of the rib.

2. Specifying the chest position

To specify the chest position, please specify the distance from the bottom of the neck rib to the center of the design, and the distance from the center of the neck rib to the center of the design in centimeters. Since the positioning is done manually, there may be a discrepancy of up to 1 cm, so please take this margin of error into consideration when ordering.

3. Regarding the processing position of the left and right edges, if you want the design to be close to the seam, please specify the measurement from the nearest seam.

4. Matching the design positions on the front and back

We do not accept work to align the designs on the front and back of a T-shirt, as this is prone to misalignment due to differences in position when laid flat and when worn, as well as individual differences.

About Inkjet

Characteristics of inkjet printing

- Because the ink is printed directly onto the clothing, it has excellent flexibility and color expression.

・You can order from just one sheet without any plate making fees.

- Printing is done at a maximum of 1200 dpi, resulting in high print precision and allowing for beautiful reproduction of detailed designs and gradations.

- Designs can be created digitally, so even full-color designs can be easily printed.

- By using white ink, you can print on dark colored fabrics.

・If you do not have white ink, the finished product will have a soft texture similar to that of a dye-submerged print.

- Using white ink will result in a print with a firm texture similar to rubber printing.

- White inkjet printing is not possible on light-colored fabrics such as natural or gray, as the treatment agent leaves strong traces. DTF printing is required. However, please note that DTF printing will not print lines less than 1mm wide.

Notes for printing on materials other than white

There are two types of inkjet printing: one that uses white ink and one that does not, and the results are different.

Normally, light fabrics such as white are printed without using white ink, and dark fabrics such as black are printed with white ink.

Printing on light fabrics without using white ink results in a natural texture that blends in with the fabric.

However, depending on the fabric color, the printed part may appear slightly transparent, so please check in advance.

In normal inkjet printing, When applied to dark colored fabrics such as black or navy, the print will appear subdued.

-If you would like white inkjet printing, we will process it using DTF printing unless specified otherwise by the customer.

Regarding the change to reflective DTF print

You can change to reflective DTF print for an additional 800 yen per location.

DTF reflective print has a metallic finish compared to regular DTF print.

In addition, the print surface may reflect light depending on the amount of light and flash used (the degree of reflection may vary depending on the environment).

The precautions for ordering are the same as for regular DTF printing, but please note the following:

- The print surface may feel rougher than regular DTF prints.

Please note that the color of the reflective print may appear slightly muted.

▽ Inkjet print processing size

As a general rule, the shipping fees are as follows, but they may vary depending on the product, so please check the product details.

W350mm x H400mm

▽Points to note when submitting your work

- Please note that objects (including lines and text) with a width of 1 mm or less and gaps of 1 mm or less may be crushed or rubbed.

・When white ink is not used, areas specified as white in the design data will be colorless. If you want to express white on items made of light-colored fabrics, please use DTF printing, which will be introduced in the future.

- When removing background images using image editing software, please do so carefully. Even a slight amount of data that is not 0% density may cause the printer to react and print, which may result in an undesired finish.

・If there is any unnecessary data remaining in the submitted data, please be sure to delete it. Since we cannot determine whether the data is necessary or not, there is a risk that unnecessary data will be printed.

- Be sure to rasterize data that includes paths or uses effects such as patterns registered as swatches. If you use graphics software such as Adobe Illustrator and do not rasterize (convert to a single image data) data that includes paths or uses effects such as patterns registered as swatches, you may not get the desired results.

・Please prepare images to be used for inkjet printing at 200 dpi or higher in actual size. If you enlarge photo data or illustration image data beyond actual size, the finished product may be rough.

・We cannot print on white, gold, silver, fluorescent colors, or special colors. Also, due to the characteristics of the processing machine, uneven areas may not print properly.

- Because the print is made directly onto the fabric, it is easily affected by the color of the fabric, and there may be discrepancies with the desired color on items other than white. Color reproduction is poor when printing onto dark colored fabrics, so if you require color reproduction, please use white inkjet printing.

- Even if you submit the same design, there may be differences in the finished color due to temperature, humidity, and individual differences in the processing machine.

▽ Additional precautions when using white ink

- As a general rule, white ink blurring effects and gradations cannot be used. Even in data areas with an opacity of less than 100%, the white background is printed clearly, making it impossible to achieve blurring or gradations using transparency processing. Also, if edges or lines are not vertical or horizontal and anti-aliasing is applied to low-resolution images, the white background will be printed in those areas, and the background may become visible.

- Be careful to remove any background images you do not want printed. When using the automatic selection tool in image editing software to select and remove a background image, the background may not be selected sufficiently, leaving some background image data behind. Also, anti-aliasing may be applied, leaving semi-transparent areas. Even if there is only a small amount of data with a density other than 0%, a white background may be applied, which may result in an undesired finish.

- Be sure to delete any unnecessary data. Even if it remains in the submitted data, it will be printed as is because it cannot be determined whether the data is necessary or not. For example, if you added a black background to check the design when creating it, if you submit it as is on a black body, the data will be printed with the background color.

▽About white ink and processing agents

- When printing with white ink, dark color processing (pre-processing) is required before printing.

・In addition, if you use white ink or print on a dark colored T-shirt, an additional 600 yen will be required per location.

・As a pre-treatment, a "pre-treatment agent" is first applied, and then heat treatment is carried out using a press. For this reason, slight stains of the pre-treatment agent or traces of the heat treatment may remain on the finished product.

- For products that have been treated with a dark color treatment, you will need to wash them promptly after delivery to remove the pre-treatment agent.

- For white and light-colored body colors, regardless of the product, traces of the dark color treatment may remain strong and may not come off even after washing, so we may use DTF (on-demand transfer) processing without notice.

・Depending on the product, dark color processing may not be possible and DTF processing may be required. Please feel free to contact us for more information.

- Regarding washing, the product will be delivered with traces of white ink pre-treatment remaining.

-If you plan to use or sell the items immediately after delivery, we can wash them for 200 yen per item.

Please note that wrinkles, shrinkage, and pilling may occur depending on the temperature and tumble dryer.

- The pre-treatment marks will gradually disappear and become less noticeable after several washes, but depending on the body color, they may remain.

- To prevent peeling or discoloration due to friction on the printed area, wash by hand or turn the item inside out in a laundry net and wash in hot water without rubbing the printed area.

- Washing with hot water will remove pre-treatment marks more effectively, but dark color treatment marks may not be completely removed in one wash.

- Please note that we cannot accept returns or re-production due to traces of pre-processing.

- Regarding uneven printing, when applying dark colors to a design with a large solid area, the finish may not be uniform, and fuzziness or unevenness like marbled fuzz may occur. However, this is not noticeable in a detailed design with a small area and many colors. Please be careful when creating your design.

About embroidery

At PRINTEEZ, we use computer-controlled automatic embroidery machines for machine embroidery. We do not charge for data creation fees, so you can order from just one piece. We can use a wide variety of threads, so a wide range of color variations is possible.

Unless otherwise specified, we generally embroider lines less than 1mm wide with a running stitch, lines 1mm wide or wider with a satin stitch or tatami stitch, and painted areas with a tatami stitch.

If the gap is less than 1mm, a "connecting thread" may be created to maintain (reinforce) the quality of the finished product. Even if a connecting thread is created, we aim for a natural finish by connecting the nearest points, but if you would like a finished product without connecting threads, please leave a gap of at least 1mm between designs.

Unless it can be achieved with a running stitch, we generally do not accept embroidery for designs that include line widths or gaps of less than 1mm.

▽Features of embroidery

-Embroidery is a method of expressing designs by stabbing thread, so it is not suitable for reproducing fine designs.

- For stretchy fabrics such as T-shirts, we recommend a line width of 3mm or more (5mm or more recommended) and a cutout line of 2mm or more.

- It is highly durable and has a woven thread structure, making it resistant to wear and tear caused by washing and use, allowing it to be used for a longer period of time than screen printing or inkjet printing.

- It can be used on cotton and polyester, as well as thick materials and small items.

- There is a high degree of freedom in design, and you can even embroider personal names or initials.

・Even small lots can be produced at low cost, making embroidery easy for individuals and small businesses. However, costs may increase depending on the size.

▽About embroidery processing size

As a general rule, the shipping fee is as follows, but it may differ depending on the product, so please check the product details.

T-shirts: W80mm x H80mm

Thick items such as sweatshirts: W80mm x H80mm, W160mm x H160mm

▽Regarding embroidery frame marks

When embroidering, a special frame is placed on a T-shirt, sweatshirt, or other garment and then set into the sewing machine. We use a special frame that does not leave marks, but frame marks may remain on some items.

We do our best to remove any marks before shipping, but please note that some may remain. After receiving the product, washing the frame will almost completely remove any marks.

We also offer a laundry service for 200 yen per item. If you plan to use or sell the item immediately after delivery, please consider having it washed by us.

Please note that washing may cause some shrinkage and wrinkles. Please note that using a tumble dryer may cause shrinkage and pilling.

Regarding misalignment of embroidery position

We use a camera to position the embroidery, but there may be a deviation of 1 to 5 mm due to individual differences in the garment and the specifications of the sewing machine.

Additionally, the embroidery position on the center front (chest) is usually produced and processed based on the center of the rib at the neck (collar). However, because clothing varies from garment to garment, the center of the rib at the neck does not necessarily coincide with the center of the body width (width). Therefore, when measuring the center front embroidery design based on the center of the body width, there may be an error of up to 5 mm.

Please note that we use the rib at the neck as a reference for the embroidery position when processing the embroidery.

▽About the misalignment between the fill and the lines

・Unless otherwise specified, we will generally embroider lines less than 1mm with a running stitch, lines over 1mm with a satin stitch or tatami stitch, and painted areas with a tatami stitch.

・Letters smaller than 14 pt (approximately 5mm high) cannot be embroidered.

- Please note that misalignment may occur in designs that include lines and fills.

- The amount of misalignment is proportional to the thinness of the lines, the size of the painted area, the softness and thinness of the fabric, and the number of colors of embroidery thread used.

- Highly stretchy materials such as T-shirts are not suitable for embroidery as they have a large painted area, and this can result in misalignment or distortion of the design.

- We recommend a design with a small painted area and thick lines.

▽About crushing of fine embroidery

- Embroidery is difficult to reproduce designs exactly as they are, and is particularly unsuitable for reproducing thin lines, complex designs, pointillism, dots, gradations, and other intricate designs.

・Thick lines and simple designs are suitable for embroidery, which will result in a more beautiful finish.

- Depending on the type of thread and number of colors used in the embroidery process, fine embroidery may become crushed.

- When creating an embroidery design, it is important to create a sample and check it before processing, and make any necessary adjustments.

▽ Regarding the design

- The recommended embroidery line width varies depending on the softness and thickness of the product's fabric.

・If you wish to embroider on a non-stretchy, sturdy fabric, please make sure the line width is at least 1mm (at least 2mm if using phosphorescent thread) for a more beautiful finish.

On the other hand, if you wish to embroider on soft, stretchy fabrics such as sweatshirts, T-shirts, or socks, we recommend that you design the line width to be at least 2mm or thicker for a more beautiful finish.

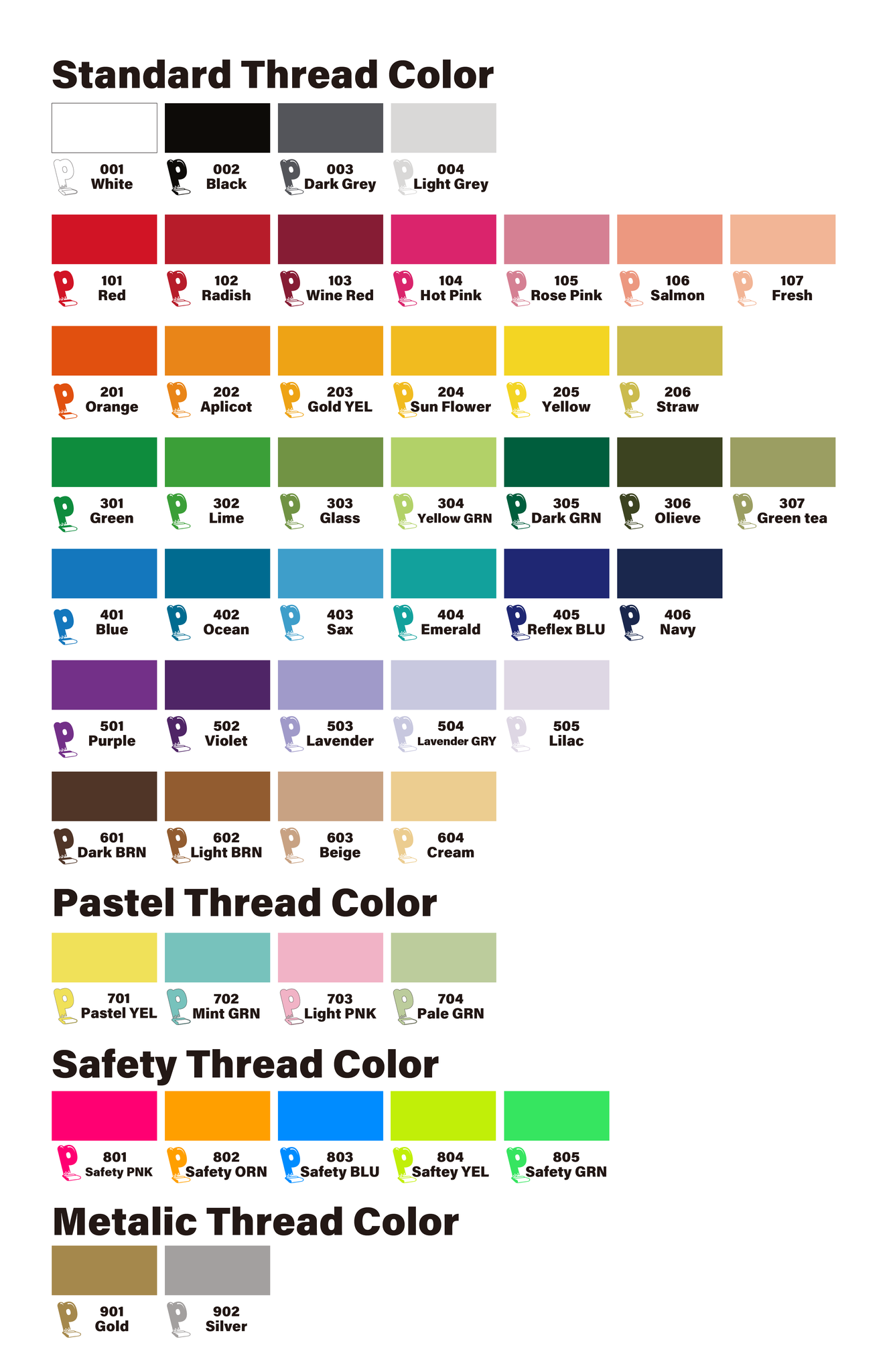

▽About embroidery thread colors

Currently, you can choose from the following five embroidery thread colors.

For the 6th color and beyond, you can add up to 10 colors (5 colors + 5 colors) for ¥200 per color.

There is no charge for changing the color of embroidery, so you can change the color of each piece individually.

We plan to add glow-in-the-dark colors in the future.

product list

-

Example product title

Vendor:VendorRegular price ¥4,300Regular priceUnit price per -

Example product title

Vendor:VendorRegular price ¥4,300Regular priceUnit price per -

Example product title

Vendor:VendorRegular price ¥4,300Regular priceUnit price per -

Example product title

Vendor:VendorRegular price ¥4,300Regular priceUnit price per